Which juice press should you choose for pressing apples and grapes?

Juice presses are widely used for producing juice from fruits and berries, as well as in winemaking. However, the large number of different juice presses available on the market creates a certain complexity when choosing. Based on many years of experience in the production and sale of juice presses, we have prepared an article that will help you navigate the wide range of presses available and make the right choice.

This article will first describe the main types of juice presses, their operating principles, and then provide recommendations for selection.

1. TYPES OF JUICE PRESSES

1.1. Screw (mechanical) juice press

Screw presses operate on the principle of a vise, compressing crushed raw materials and separating juice from the solid part — the pomace.

1.1.1. Juice press with a screw coming from the base

This is the cheapest option for a manual juice press. The screw is welded to the base of the press and comes directly from the juice collection tray. When choosing this type of press, pay attention to the height of the working thread relative to the top point of the press basket. The thread should be above the upper line of the press basket, and the lower part of the screw must be painted or made of stainless steel. Food-grade plastic grease must be used for lubricating the screw (contact with food products must be permitted). However, during the operation of such a design, wear products along with the grease may get into the juice. Additionally, the central screw complicates the use of a whole bag for filtration and the quick emptying of the press basket.

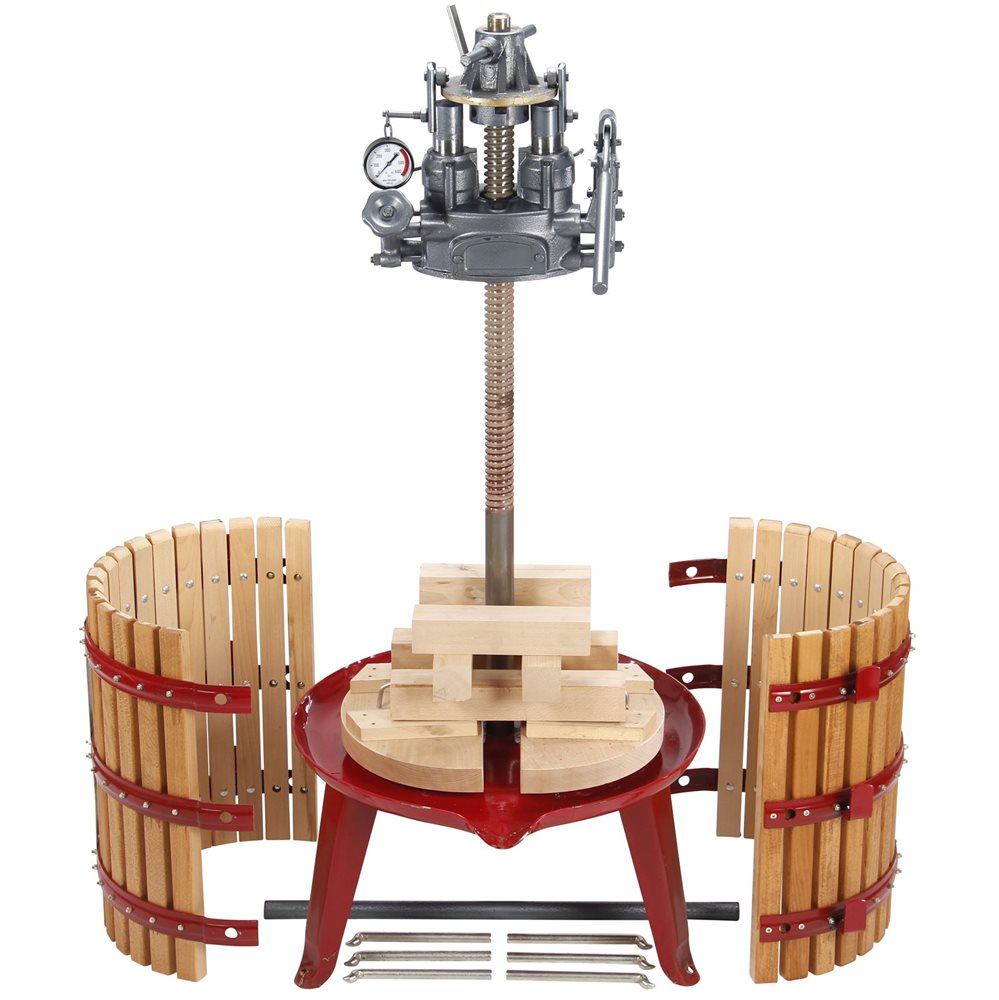

Figure 1.1. Press with a screw coming from the base VBP-10 (Manufacturer: APPLE PRESS LTD.)

1.1.2. Screw juice press with a ratchet mechanism

The ratchet mechanism of the press significantly simplifies the juice extraction process, as it creates an additional lever. However, the process of tightening the screw using the ratchet mechanism is quite time-consuming, so this type of press design is advisable only for large-volume presses. For small presses with a basket volume of up to 20 liters, it is better to choose a frame design.

Figure 1.2. Screw press with a ratchet mechanism (Manufacturer: ZAMBELLI Enotech s.r.l.)

1.1.3. Screw juice press with a jack mechanism

The jack mechanism of the press significantly speeds up the juice extraction process and allows for greater pressure. It is usually applied to presses with a basket volume of 128 liters or more.

Figure 1.3. Screw press with a jack mechanism (Manufacturer: ZAMBELLI Enotech s.r.l.)

1.1.4. Frame screw juice press

In this variant of the screw press for fruits, the screw is located at the top and rests on a special pad on the press piston, so the screw lubrication does not get into the juice.

Frame screw presses are convenient to use, as juice can be extracted in one go by tightening the screw to the limit without moving anything during the extraction.

However, when the basket volume exceeds 10-20 liters, turning the screw can be quite tiring, especially if a large quantity of apples or grapes needs to be processed.

Small frame screw presses with a basket volume of up to 5 liters are convenient for use in the kitchen. They are lightweight and compact, so they can easily fit on a shelf and do not take up much space.

The bearing support and bronze bushing in the pad on the piston significantly facilitate the rotation of the screw and ensure the reliable operation of the friction parts.

Pay attention to the length of the thread in the press frame. Often, when cutting the thread in the round nut of the frame, part of the length of the hole is machined to the outer diameter of the screw, and only in the remaining 2-4 centimeters is the thread itself cut. For reliable and long-lasting operation of the press, the thread should be cut along the entire length of the nut, which is 5-7 cm for trapezoidal screws TR24x5 or TR28x5.

Figure 1.4. Frame screw juice press VP-20 (Manufacturer: APPLE PRESS LTD.)

1.2. Hydraulic juice presses

1.2.1. Juice press with a jack on top of the basket

The hydraulic press for apples and grapes consists of a power rectangular frame with a support for the jack rod in the center. With the help of the jack, one can easily create high pressure without exerting excessive effort. The only downside is that the stroke of the jack rod is not sufficient for the entire height of the basket. Because of this, during the juice extraction process, wooden blocks need to be placed underneath. This problem can be solved by purchasing a two-stage jack.

Figure 1.5. Hydraulic press for apples GP-30 (Manufacturer: APPLE PRESS LTD.)

Video 1.1. Using the apple press GP-26s with a two-stage jack (Manufacturer: APPLE PRESS LTD.)

1.2.2. Juice press with a jack underneath the basket

In this design of the fruit press, the jack is located underneath, lifting the press basket with the tray upwards. The position of the piston is fixed through a special support at the top of the frame.

Figure 1.6. Juice press with a jack underneath the basket VARES, 18 l (Manufacturer: VARES Mnichovice a. s.)

1.2.3. Hydraulic juice press with a screw (with jack and screw)

The screw is used for the first stage of juice extraction, when juice is released with a small effort. The remaining juice is extracted using the jack located underneath.

Figure 1.7. Homemade juice press with a screw and hydraulic jack

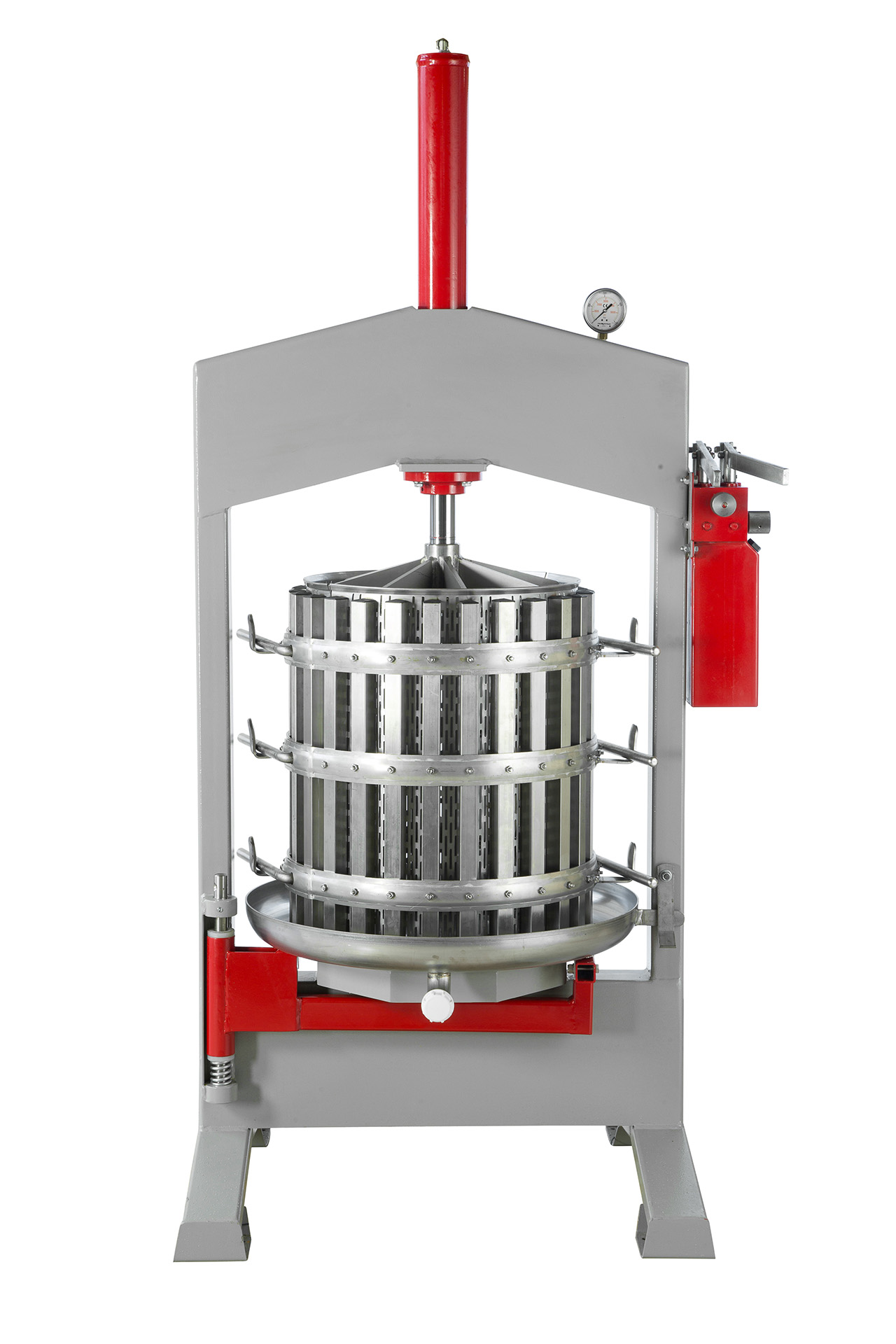

1.2.4. Juice press with a hydraulic cylinder and manual pump

This design refers to an industrial press for apples. The frame of such a press contains a hydraulic cylinder, as well as a manual pump, which supplies hydraulic oil to the piston of the cylinder. Such a press for apples has a high productivity and basket volume (50, 100, 200 liters or more). It is very convenient to extract juice with such a press, as the stroke length of the piston is designed to be sufficient for the entire working height of the barrel.

However, due to the more complex design, the price of such a press is much higher, and the press design is justified only for professional use - for a direct juice production line or a small winery.

Figure 1.8. Juice press with a hydraulic cylinder and manual pump O.F.B.M. INOX (Manufacturer: Fratelli BAESSO s.n.c.)

1.2.5. Juice press with a hydraulic cylinder and hydraulic station

For juice extraction on such a press, it is enough to press the handle of the hydraulic distributor and ensure that the juice has time to separate from the pomace and that the nominal allowable pressure is not exceeded.

Figure 1.9. Juice press with a hydraulic cylinder and hydraulic station O.F.B. INOX (Manufacturer: Fratelli BAESSO s.n.c.)

1.2.6. Juice press with a hydraulic cylinder with automatic juice extraction function

This is a semi-automatic electric press for grapes and apples. Juice extraction occurs automatically after pressing one button, while loading and unloading of raw materials is done manually.

Figure 1.10. Juice press with a hydraulic cylinder with automatic juice extraction function ATON (Manufacturer: ZAMBELLI Enotech s.r.l.)

1.3. Belt press for juice extraction

The belt press operates on the principle of continuous juice extraction from crushed apple mass, which is fed onto a moving belt directly from the crusher and is compressed between rotating rollers or between two belts. The resulting juice drains into containers located below, while the pomace left after extraction is removed.

Belt presses are usually used on automatic direct juice production lines and have a capacity ranging from 400 kg to 3000 kg of apples per hour.

Figure 1.11. Belt press for juice extraction POWERPRESS 400 (Manufacturer: JSC “ProFruit Machinery”)

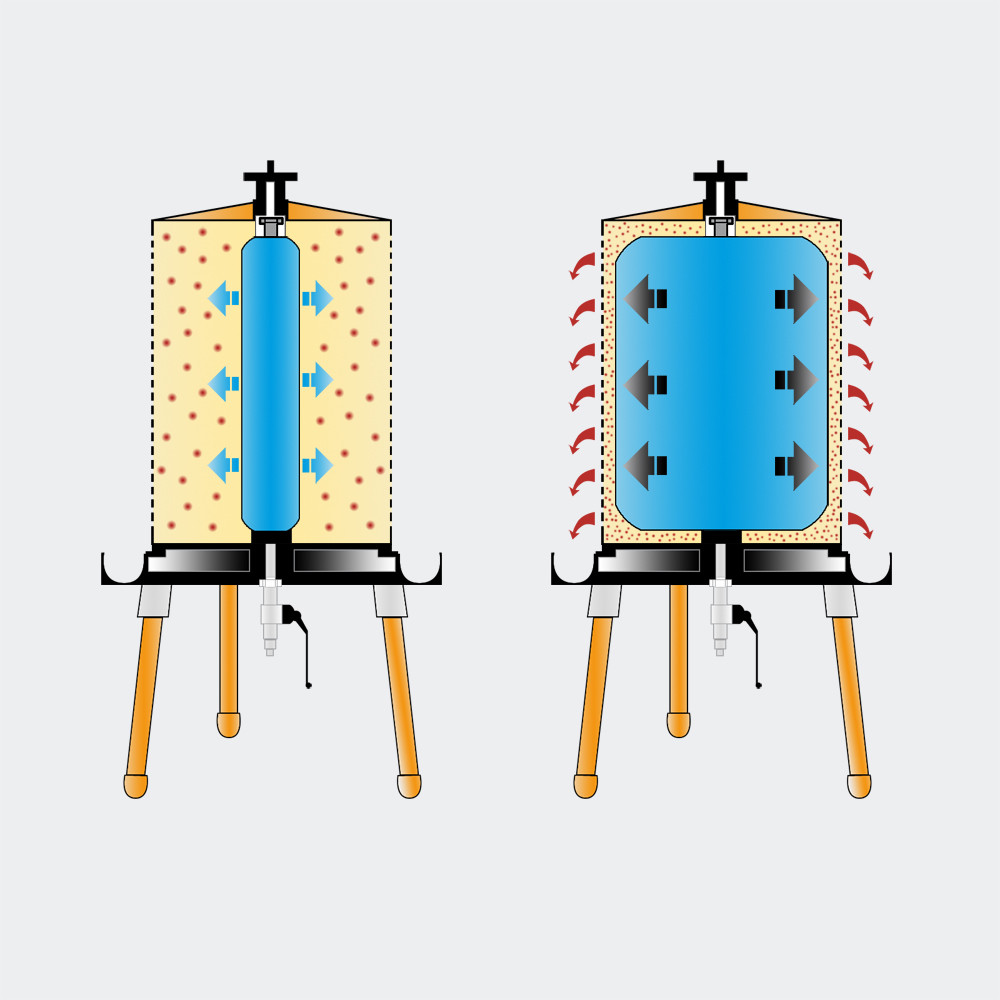

1.4. Hydro press for squeezing juice from apples and grapes

This press extracts juice using water pressure from the water supply. Crushed raw materials are placed into a stainless steel basket, and the lid is closed.

In the center of the basket is a rubber membrane, which expands under water pressure to extract juice. The juice extraction process occurs automatically. The press requires a water supply with a pressure of 2-3 atmospheres.

Figure 1.12. Operation principle of the hydro press with a rubber membrane

Such presses for making juice from grapes and apples are produced with a basket volume ranging from 20 to 450 liters. The price of such a press for 20-40 liters is several times higher than that of a similar hydraulic or screw press. Hydro presses also have a lower juice yield than hydraulic presses for apples, so it is more reasonable to purchase a hydro press with a basket volume of 90 liters or more. The membrane of the hydro press wears out over time and needs to be replaced.

Figure 1.13. Hydro press for juice SPEIDEL, 20 l

1.5. Pneumatic juice press

The principle of operation of the pneumatic press is similar to that of the hydro press, except that compressed air from a compressor is used instead of water to expand the membrane.

1.5.1. Vertical pneumatic press with a membrane for juice extraction

In the center of the basket of such a press is a rubber membrane, which expands under air pressure to extract juice.

Figure 1.14. Pneumatic juice press PEA40, 40l (Manufacturer: Grifo Marchetti Srl)

1.5.2. Vertical pneumatic press with a pneumatic cushion

In this design of the pneumatic press, a pneumatic cushion serves as the actuating mechanism, which expands under air pressure and presses on the piston of the press. The working air pressure in such presses is approximately 5-7.5 bar.

Figure 1.15. Vertical pneumatic press with a pneumatic cushion "Muromets P", 29 l (Manufacturer: LLC "Forkom")

1.5.3. Horizontal pneumatic press with a membrane

Membrane pneumatic presses play an important role in the production of high-quality wines. Such presses ensure very gentle and controlled extraction of juice from berries or apples, which directly affects the quality of the wine.

Figure 1.16. Horizontal pneumatic press with a membrane PN ZETA-S (Manufacturer: ZAMBELLI Enotech s.r.l.)

In a pneumatic press, clusters of grapes or must are located inside a closed drum, and an inflating membrane acts on them. The pressure is distributed evenly and gradually, minimizing the crushing of seeds and damage to the skin. This allows for the initial extraction of "free run" (the gentlest juice), followed by denser fractions without mixing them. Closed-type presses can operate in an inert gas atmosphere, preventing oxidation of the juice.

Additionally, the pneumatic press yields juice with a lower content of suspended solids and particles, reducing the need for additional filtration.

Video 1.2. Using the horizontal pneumatic press with a membrane

When producing apple juice, open-type pneumatic presses with grids (perforated basket) are often used, where slight oxidation of the juice is not critical.

1.6. Bag press for juice

Crushed apples are layered in fabric bags a few centimeters thick using a special stainless steel frame. The edges of the bags are turned over, and wooden grids or plates are placed between the bags. A pressing plate is placed on top. Then, using a screw or hydraulics, the bags with grids are compressed, and juice flows out between the plates.