The best juicer for apples (review)

When choosing an apple juicer, it is necessary to determine the main goals and answer the following questions:

- 1) What do you plan to use the juicer for?

- 2) What final product do you intend to obtain (juice, cider, apple vinegar)?

- 3) What performance is required (l/h)?

- 4) What is the planned frequency of use — periodic processing of the harvest several times a year or daily operation (several times a year for processing apples or every day)?

- 5) Is it planned to extract juice exclusively from apples, or will the device also be used for other fruits, berries, and vegetables?

In addition, it is important to consider the materials used in the juicer's construction, the quality of assembly, the reliability of the design, and the availability of spare parts, especially in the case of planned commercial use of the equipment. It is also important to pay attention to the quality of the juice obtained.

1. JUICER DEVICES

There are 3 main types of apple juicers:

- 1) centrifugal juicers;

- 2) masticating juicers;

- 3) juice presses (mechanical juicers for apples);

Let's take a closer look at the devices of these types of juicers.

1.1. Centrifugal Juicer for Apples

Centrifugal juicers are the most common due to their affordable price and ease of use.

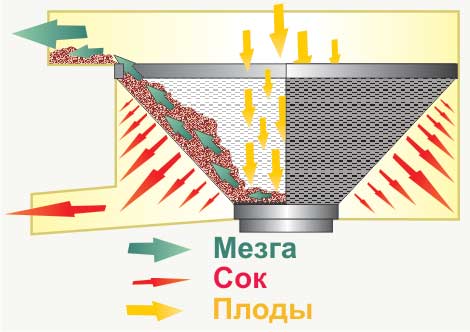

The apple is crushed with a disc with a fine grater into a mash, and due to centrifugal force, the crushed apple mass is pressed against the walls of the separator, which is made of a mesh with small cells. The juice seeps through the mesh of the separator and flows out through an opening. The pomace is ejected from the other side into a special container.

Figure 1. Diagram of the centrifugal juicer separator operation

By the shape of the separator, centrifugal juicers are divided into cylindrical and conical.

1.1.1. Centrifugal Juicer with Conical Separator

Due to the conical shape of the separator, the apple pomace is ejected into the receiving container under the influence of centrifugal force.

Figure 2. Conical separator of the MIRACLE EDITION 68 centrifugal juicer (Manufacturer: SANTOS S.A.S.)

1.1.2. Centrifugal Juicer with Cylindrical Separator

Centrifugal juicers with a cylindrical separator need to be periodically cleaned of accumulated pomace manually, as is the case with domestic apple juicers "Salut", "Neptune" or "Rossoshanka". This can also be done with a special lever that allows for the discharge of accumulated pomace. The Belarusian juicer "Zhuravinka" operates on this principle.

The "Salut" apple juicer has a sufficiently high output, and due to its wide neck, whole apples can be fed into it. The downsides of such a juicer are noise and significant vibration. The neck needs to be literally covered with hands to prevent product ejection during the operation of the device. Periodically (after extracting 2-3 liters of juice), it is necessary to remove the lid, take out the mesh with pomace, and clean it.

Figure 3. Cylindrical separator of the centrifugal juicer SVPR-201 "SALUT" (Manufacturer: PJSC "Penzmash")

1.2. Masticating Juicer for Apples

The design of a masticating juicer is somewhat similar to a meat grinder. The central part of the masticating juicer is a plastic or metal auger with grooves along which apples spiral downwards. As the auger pushes the apples through the spiral, they are ground against the walls of the mesh filter. Juice flows out through the walls of the filter, and dry pomace is produced at the exit from the juicer. The juice is collected in a bowl and flows out.

Figure 4. Principle of operation of the masticating juicer

Professional masticating juicers often have a crushing device installed before the auger itself, allowing whole apples to be fed in without preliminary cutting.

Figure 5. NUTRISANTOS masticating juicer with a pre-cutting knife (Manufacturer: SANTOS S.A.S.)

There are horizontal, vertical, single-auger, and dual-auger juicers.

Figure 6. ANGEL JUICER 7500 masticating juicer (Manufacturer: ANGEL JUICER)

Hand-operated masticating juicers are not suitable for extracting juice from apples, as apples need to be cut into small pieces, and turning the handle can be quite tiring.

Figure 7. Manual masticating juicer

1.3. Apple Press

An apple press is the oldest traditional method of obtaining juice from apples and grapes. Such presses were used even in ancient times. The essence of the method is simple: apples are crushed into small pieces, and then mechanically (manually or using a lever, screw, and later hydraulics) the apple pomace is squeezed to obtain juice.

Figure 8. Hydraulic juice press GP-26 (Manufacturer: APPLE PRESS LTD.)

The press is especially indispensable in winemaking. It occupies a central place in the wine and cider production process, especially at the stage of separating juice from pomace. Without it, it is impossible to effectively obtain juice from apples and grapes, especially in large volumes.

Even at factories producing direct-pressed apple juice, the same technological process is used, only all processes are mechanized and automated. Usually, such juice extraction lines use belt-type presses.

Figure 9. Belt press for juice + washing-elevator-fruit crusher (Manufacturer: JSC “ProFruit Machinery”)

2. WHICH APPLE JUICERS ARE BETTER AND WHICH JUICER TO CHOOSE?

When choosing an apple juicer, attention should be paid to 7 main factors:

- 1. Purpose of use

- 2. Quality of the obtained juice

- 3. Juice yield

- 4. Reliability and serviceability

- 5. Noise level

- 6. Price

- 7. Ability to extract juice from other fruits, berries, and vegetables

2.1. Purpose of Use

2.1.1. For daily use in the kitchen

If you plan to extract several glasses of fresh apple juice every day, any medium-powered centrifugal or masticating juicer can easily handle this.

Masticating juicers provide a sufficiently high juice yield. However, fruits need to be cut into wedges and a pusher must be used, so the productivity is very limited.

You can also buy a kitchen press with a basket volume of 3-5 liters, made of stainless steel. For crushing apples, you can use an electric potato grater with an apple attachment.

As a result, you get a complete set of a press and a grinder at the price of a semi-professional centrifugal or masticating juicer. And the potato grater will always come in handy in your kitchen for making potato pancakes or cepelinai.

Figure 10. Screw juice press VP-3s (Manufacturer: APPLE PRESS LTD.)

Video 1. Potato grater BETM-1 with apple knives (Manufacturer: UAB MIGIRIS)

2.1.2. For wine or cider production

When producing cider or apple wine, apples are first crushed. Before pressing, the crushed mass (pomace) is allowed to steep for some time. This process is called maceration (Latin maceratio, from Latin macero — to soften, soak). A press is necessary for extracting the fermented mash from apples. The press allows for quick and efficient juice extraction.

A centrifugal juicer cannot handle such raw materials — it will not be able to effectively separate juice from the semi-fermented mass.

Moreover, foam, sediment, and yeast will get into the juice, interfering with the further process.

This is especially important in traditional cider making, where prolonged maceration of up to 24 hours is often used.

2.1.3. For preparing juice for winter or small-scale production

A masticating juicer for apples has too low a productivity, so it is impractical to use it for preparing apple juice.

If you want to use a centrifugal juicer for preparing juice from apples, you need to buy a powerful juicer with high productivity, a conical separator shape, and a large neck. Whole apples can be placed into such a juicer. It is better to buy a high-performance juicer made of stainless steel. The productivity can reach several buckets of juice per hour.

However, the most effective equipment for processing a significant volume of apples is a press. With a press, you can prepare a huge amount of juice for winter. In one go, using a 20-liter press, you can extract a bucket of juice. This takes about 5 minutes. Thus, with a high-performance juicer, if 3 people are working in the garden (one washes apples, another grinds, and the third extracts juice), more than 100 liters of juice can be extracted per hour.

Figure 11. Hydraulic juice press GP-30 (Manufacturer: APPLE PRESS LTD.)

Additionally, a press can be used to extract juice from grapes, various berries, and other fruits and vegetables (carrots, beets, pumpkins). The larger the press and the more powerful the grinder, the more juice can be extracted in a given time. A large press with a basket volume of 100 liters or more is already an industrial apple juicer with high performance.

2.1.4. For bars, cafes, or restaurants (HORECA)

If you need to extract a glass of juice and serve it immediately, it is best to choose a professional centrifugal or masticating juicer. Such juicers are designed for daily use for commercial purposes and have a high service life, as well as spare parts available.

If you plan to prepare fresh juices for 1-2 days, store them chilled, and serve them to customers as needed, it is best to use a press and grinder for apples. This allows you to prepare a large amount of juice much faster, the juice is of higher quality with less pulp content, and there is no need to remove foam.

A press is also often used in restaurants to extract excess juice from grated potatoes when making cepelinai.

2.2. Quality of the Obtained Juice

There are many differences between various types of juicers, but the main one is the quality of the final product.

The most delicious and healthy juice is obtained using a press.

Juice obtained with a press is homogeneous, without sediment, dense, and rich.

Juice extracted with a centrifugal juicer is heterogeneous, with a thick layer of foam and sediment.

Juice obtained with a masticating juicer is much better than that from a centrifugal juicer, but still inferior to that from a press.

Presses and masticating juicers retain significantly more beneficial vitamins, enzymes, and aromatic substances in the juice, as the product does not heat up during grinding and is not blown by a high-speed airflow, as is the case with centrifugal juicers.

It is worth noting that when crushing apples with a grinder and subsequently pressing the apple mass with a press, the apple seeds remain intact. This helps avoid the undesirable bitterness imparted by crushed seeds. The resulting juice is clean, without pulp, without foam (which centrifugal and masticating juicers cannot boast of), and the taste remains rich.

Figure 12. Apple juice extraction using different types of juicers (1 - centrifugal juicer, 2 - masticating juicer, 3 - apple press GP-12s)

2.3. Juice Yield

- Centrifugal juicer: 50-60%

- Apple press: 50-70%

- Masticating juicer: 60-75%

Centrifugal juicers do not extract juice completely. The apple pulp remains moist, especially if the apples are soft. This makes this method uneconomical, especially for large volumes.

When using diaphragm filters or wooden grids that divide the crushed mass into thin layers and provide more effective juice drainage, the juice yield percentage from presses can be increased.

Figure 13. Example of using diaphragm filters for juice extraction with a press

2.4. Reliability and Serviceability

Any juicer can break down over time, so when choosing a centrifugal or masticating juicer, it is advisable to prefer more expensive models. Such juicers have fewer plastic parts. The motor in such models is more powerful and reliable and is designed for long loads. It will not overheat during operation. It is also worth paying attention to the availability of spare parts, so that in case of a breakdown, you can replace the worn part instead of buying a new juicer.

As for hydraulic presses made entirely of stainless steel, this is a purchase for a lifetime. During prolonged use, only the hydraulic jack may break down, and it can always be bought at the nearest auto parts store for 10-15