Juice pasteurizers: equipment classification and selection recommendations

After squeezing, juice must be pasteurized to destroy harmful microorganisms and extend shelf life. This process helps preserve the taste and beneficial properties of the product without adding preservatives.

According to their design, juice pasteurizers can be:

1. BATCH JUICE PASTEURIZERS

1.1. Stainless Steel Pot

This pot is ideal for juice pasteurization. However, attention should be paid to the grade of stainless steel from which the pot is made. Juice is an acidic medium, and it is better to choose highly alloyed corrosion-resistant stainless steels of grades AISI 304 (18/10). The Russian equivalent is 08Х18Н10. Gas, electric, and induction burners can be used to heat the juice in the pot.

1.2. Juice Pasteurizer with Built-in Electronic Thermometer

If a drain valve for pouring and a built-in thermometer with an audible indicator for reaching the set temperature are added to the pot, it becomes a pasteurizer.

Figure 1. Juice Pasteurizer SP-50 (Manufacturer: APPLE PRESS LTD.)

1.3. Autoclave as a Juice Pasteurizer

A conservator - autoclave can also be used for juice pasteurization. This device usually has an electric heater with a temperature regulator and several heating programs, as well as a drain valve that is convenient for pouring hot juice.

Figure 2. Autoclave DOMO DO42326PC

1.4. Juice Container with Floating Lid and Immersion Tube Heater

The pasteurizer operates on the principle of a regular household kettle, which is immersed in a container with juice. At the bottom of the juice container, there is a drain valve that is convenient for pouring hot juice. The juice container with a floating lid can also be used for storing pasteurized juice.

Read more: How to Preserve Juice for Winter - 9 Methods

Figure 3. Juice Pasteurizer SPEIDEL 65 l - 170 l with immersion heater

1.5. Insulated Container for Juice Pasteurization

The pasteurizer operates on the principle of a regular household kettle, which is immersed in a container with juice. At the bottom of the juice container, there is a drain valve that is convenient for pouring hot juice. Due to the double walls of the pasteurizer, heat loss during juice heating is minimized, and the set temperature is maintained during pouring.

Figure 4. Insulated stainless steel container for juice pasteurization 80 l – 150 l (Manufacturer: Helmut Rink GmbH)

1.6. Boiler for Cooking Jam and Pasteurizing Juice or Milk

The pasteurizer's container has double walls and is made entirely of stainless steel. Heating can be done using electric heating elements with glycerin or water from an external heat source (e.g., diesel or gas boiler).

The pasteurizer has adjustable speed, built-in fully automatic control of temperature and pasteurization time.

The integrated mixer with scrapers prevents product from sticking to the walls.

The touch panel allows setting recipes, time, temperature, and mixing speed.

Figure 5. Jam and jelly cooking pot with mixer 200 l - 500 l (Manufacturer: ProFruit Machinery)

1.7. Immersion Type Pasteurizer (Water Bath Based Pasteurizer)

Fresh juice is poured into bottles, caps are placed on the necks (not screwed on completely). The bottles are placed in special trays and put into a bath, then water is poured in until it reaches the neck of the bottle. The water in the bath is heated using heating elements or an external heat source. When the set temperature is reached, a timer is activated, and pasteurization begins. During this time, filled bottles can be loaded into a new set of trays for a faster exchange process.

When the pasteurization time is up, the bottles are unloaded, the caps are tightly screwed on, and the bottles are turned upside down.

Since the temperature is measured only in the bath, it is important to monitor the temperature of the juice in the bottles to ensure compliance with the pasteurization process.

This method can be used for glass bottles, jars, tin cans, and any other heat-resistant packaging.

It works with various products such as juice, jam, marmalade, puree, sauce, etc.

Figure 6. Juice Pasteurizer Bath (Manufacturer: ProFruit Machinery)

2. CONTINUOUS (TUBULAR) JUICE PASTEURIZERS

In this type of juice pasteurizers, water is heated using heating elements, in which a coil (heat exchanger) through which juice flows is located. This reduces the time of thermal exposure to the juice and achieves continuity of the process.

2.1. Pot with Coil

The pot is placed on a gas, induction, or electric burner. Once the working temperature of the water is reached, juice pasteurization can begin. It is necessary to monitor the temperature of the juice at the outlet to ensure it does not drop below 80 degrees. This can be achieved by adjusting the flame power of the burner or changing the flow rate of the juice through the coil.

Figure 7. Coil Type Continuous Pasteurizer PAS 50 (Manufacturer: ZAMBELLI Enotech s.r.l.)

There are also similar pasteurizers with a heating element already installed inside the pot.

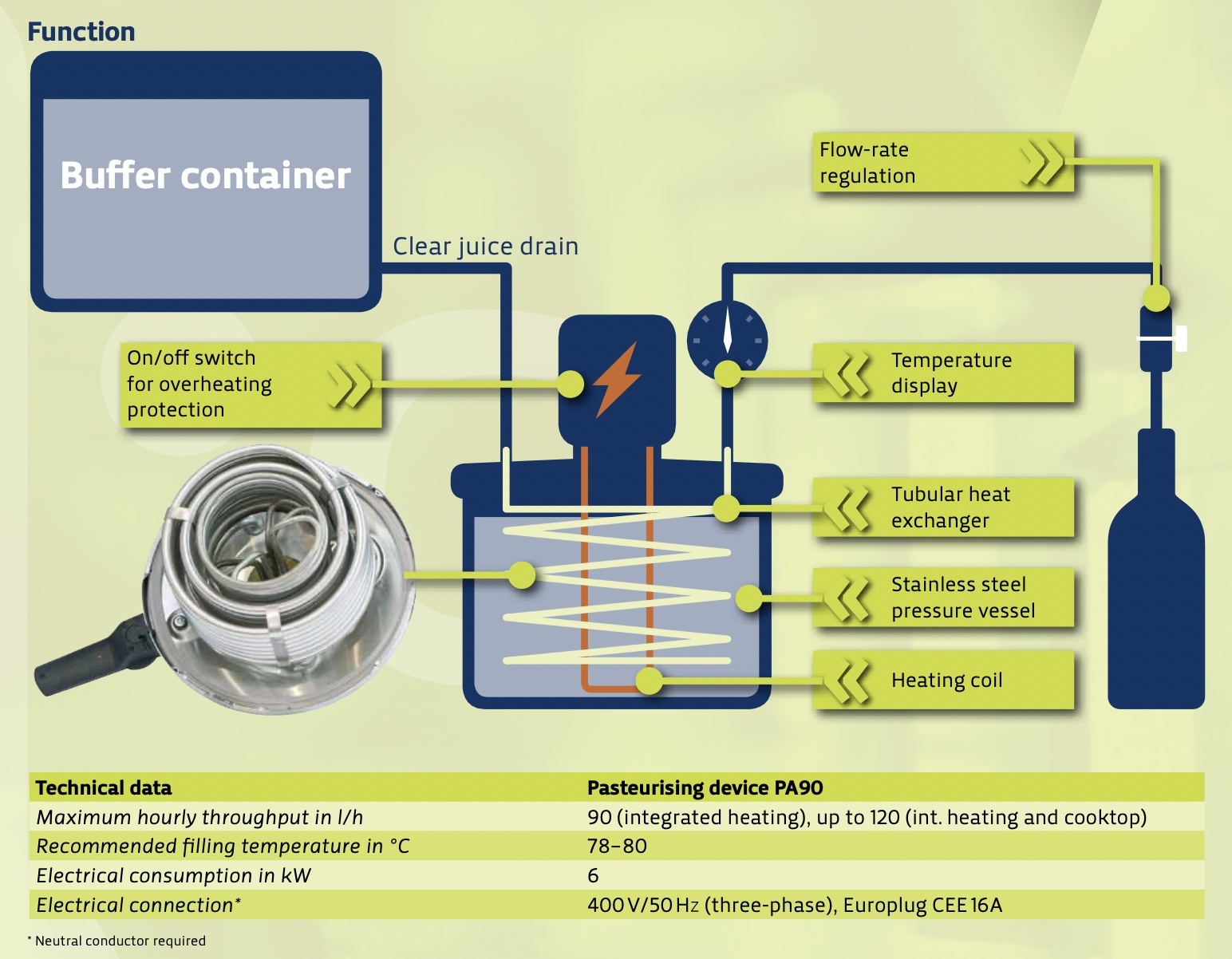

Figure 8. Coil Type Continuous Pasteurizer with Electric Heater PA90 (Manufacturer: VORAN Maschinen GmbH)

Figure 9. Functional Diagram of Juice Pasteurizer VORAN PA90

2.2. Semi-Automatic Electric Juice Pasteurizer with Heat Exchanger

The water tank is filled to the level of the sensor. After heating the water to the working temperature, juice is poured into the upper tank, and a digital thermometer is turned on to monitor the juice temperature. The juice temperature at the outlet needs to be adjusted manually. The pasteurizer is equipped with 2 nozzles for pouring juice into glass bottles and a table for Bag-in-Box packages.

Figure 10. Semi-Automatic Electric Juice Pasteurizer with Heat Exchanger PA180E (Manufacturer: VORAN Maschinen GmbH)

2.3. Automatic Juice Pasteurizer with Heat Exchanger

In this type of pasteurizers, all heating and juice temperature control processes are automated. The pasteurizer is connected to the juice production line, and it only remains to pour the juice into bottles or other containers.

Figure 11. Automatic Electric Juice Pasteurizer with Heat Exchanger EHA 27E (Manufacturer: Gebhardt Anlagentechnik GmbH Co.KG)

Such pasteurizers can be electric, diesel, or gas.

Figure 12. Automatic Diesel Juice Pasteurizer with Heat Exchanger HEAT 3000 (Manufacturer: ProFruit Machinery)

There are also pasteurizers combined with a filling installation for Bag-in-Box® and “Stand up Pouch”. The system includes a diesel pasteurizer, a semi-automatic Bag-in-Box filler, and a buffer tank, forming a comprehensive, mobile solution for optimizing production.

Figure 13. Pasteurizer with Heat Exchanger Combined with Juice Filling Installation (Manufacturer: ProFruit Machinery)

2.4. Pasteurizer with “Tube in Tube” Heat Exchanger

The “tube in tube” heat exchanger is specifically designed for heating or cooling products with medium and high viscosity (e.g., puree, berries, etc.). Its biggest advantage is the ability to process products with fibers or particles without the risk of clogging.

The pasteurizer consists of a heat exchanger with two concentric tubes. Juice flows through the inner tube, while heating occurs through the outer tube with water.

Water can be heated using external heaters with diesel fuel (oil), gas, or electricity, as well as supplied from another heat source.

Figure 14. Pasteurizer with “Tube in Tube” Heat Exchanger (Manufacturer: ProFruit Machinery)

According to the type of heating element, juice pasteurizers can be:

Electric Pasteurizers

Small household pasteurizers are convenient for use in home settings and small farms.

Industrial electric juice pasteurizers have a higher power heating element, so they usually operate from a 3-phase network (380 volts) and require a large power connection.

Gas Pasteurizers

Since such a juice pasteurizer does not require connection to the electrical network, it can be used anywhere, even on mobile juice production lines.

The industrial pasteurizer has a digital thermostat that provides automatic control of water temperature.

Diesel Pasteurizers

Diesel pasteurizers are also often used on mobile juice extraction lines. When using a diesel pasteurizer indoors, a pipe for exhaust gas removal must be provided.

The choice of pasteurizer is primarily determined by the cost of energy resources, the availability of the necessary power connection, and the required capacity.

We are manufacturers of juice extraction equipment. In our online store, you can purchase both small household pasteurizers and industrial pasteurizers necessary for the production line of natural direct-pressed juices.

© APPLE PRESS LTD. All rights reserved.

Copying, distributing, and using text, images, or any other materials from the site without the written permission of the copyright holder is prohibited.