Which apple grinder to choose?

Fruit crushers help prepare raw materials from apples, pears, other fruits, and berries for subsequent juice extraction. After grinding, the fruits are well-suited for pressing, which ensures the best juice yield.

When choosing an apple crusher, pay attention to the materials from which the crusher's parts are made, the quality of manufacturing, the design, performance, and the resulting fraction. All of this affects the quality of the final product (juice, cider, wine, apple vinegar).

First, the article will describe the main types of apple crushers and their design, followed by tips for choosing a crusher.

Types of apple crushers and shredders:

Manual or mechanical apple crushers for juice

Manual apple crusher with a wooden cylinder and self-tapping screws

This is the simplest design of a manual apple crusher that can be easily made by oneself. However, during grinding, the apples need to be pressed against the crushing cylinder.

Figure 1. Manual crusher RS-1 (Manufacturer: APPLE PRESS LTD.)

Manual apple crusher with a large diameter crushing cylinder

Due to the large diameter of the crushing cylinder, the apples are captured automatically and do not need to be pressed.

Video 1. Manual crusher RS-2 (Manufacturer: APPLE PRESS LTD.)

Manual apple crusher with two crushing cylinders and knives

The design of such a manual mechanical fruit crusher consists of a body with two crushing rollers and knives that rotate towards each other. The knives crush the apples, while the rollers capture them and push them down, breaking them into smaller pieces.

Figure 2. Manual crusher BAESSO 100 (Manufacturer: Fratelli BAESSO s.n.c.)

Drill-powered crushers (apple crushers from drills)

Bucket apple crusher

The design of such a crusher consists of a plastic bucket, on the lid of which there is a centering bushing for the knife. Apples are poured into the bucket, the bucket is closed with a lid with the inserted knife, and the lid is secured. The knife is then clamped in the drill chuck, and with reciprocating movements of the rotating knife, the apples are crushed in a few minutes. A stop ring limits the depth to which the knife descends to avoid damaging the plastic bucket. This crusher is universal and suitable for any fruits, vegetables, grapes, and apples and berries.

Figure 3. Apple and grape crusher CD-1 (Manufacturer: APPLE PRESS LTD.)

Apple crusher with a crushing cylinder in a wooden or stainless steel body

Usually, a wooden cylinder with self-tapping screws is used as the cylinder, arranged so that the heads of the screws protrude by 6-8mm.

Figure 4. Crushing cylinder made of stainless steel for crusher DS-2 (Manufacturer: APPLE PRESS LTD.)

Also, a potato grater with large holes can serve as a crushing cylinder.

Figure 5. Apple crusher DS-2 (Manufacturer: APPLE PRESS LTD.)

Electric crushers (apple, fruit, and vegetable shredders)

Electric potato grater with apple knives

The simplest and cheapest option for crushing apples in small quantities is an electric potato grater with apple knives. This attachment is great for apples and other fruits. This grater's performance is perfect for a screw press with a volume of 3-5 liters. The only downside is that the apples will need to be cut in half.

Video 2. Potato grater BETM-1 with apple knives (Manufacturer: UAB Migiris)

Electric apple crusher with a large potato grater

A piece of thin stainless steel sheet with elements of a large potato grater is attached to a large diameter wooden cylinder or a stainless steel cylinder. The crushing cylinder is mounted on a shaft in a housing with 2 bearings and is connected to an electric motor via a belt or flexible coupling.

Figure 6. Apple crusher EVS-055 (Manufacturer: APPLE PRESS LTD.)

Electric apple grater

This type of fruit crusher has a disc made of stainless steel with punched holes and sharpened cutting cells (like a large grater in your kitchen that you use to grate carrots).

The design of such an apple crusher is simple and reliable. Due to the angle between the pipe and the cutting disc, the apples are automatically captured during grinding and do not need to be pushed by hand.

This apple crusher can also be used for crushing grapes. The grater operates at low speeds, and the crushing disc does not damage the integrity of the grape seed, and the stem remains intact and is pushed through the gap between the crushing disc and the crusher lid. If you plan to make wine rather than juice, it is better to separate the berries from the stems before crushing. Thus, the apple crusher with the grater disc can be used for both cider production and for crushing grapes in winemaking.

Figure 7. Electric apple crusher ESE-018 (Manufacturer: APPLE PRESS LTD.)

Electric apple crusher with a disc with cutting blades

This type of apple crusher consists of a body with a pipe for feeding fruits, which, upon reaching the crushing disc with two blades, exit through the outlet.

The disc has additional blades in the center for preliminary crushing of fruits, as well as to prevent apples from getting stuck in the center.

Figure 8. Electric fruit crusher FRUIT SHARK (Manufacturer: VARES Mnichovice a. s.)

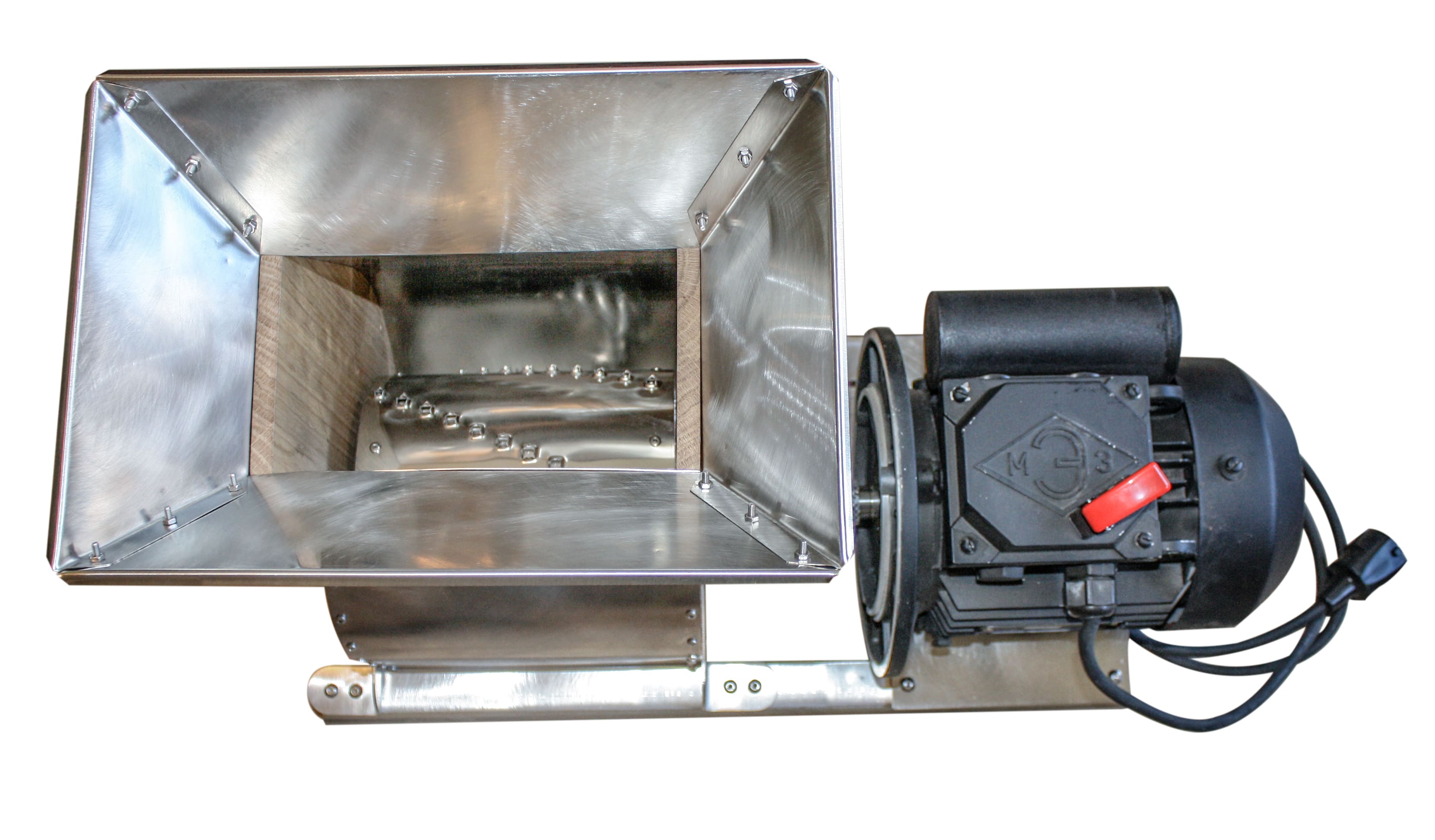

Electric apple crusher with 2 crushing cylinders

The crusher consists of a body with a receiving hopper and 2 rollers that rotate towards each other, capturing and grinding the fruits.

The motor is connected via a belt drive.

Video 3. Apple crusher PIPMO (Manufacturer: Grifo Marchetti Srl)

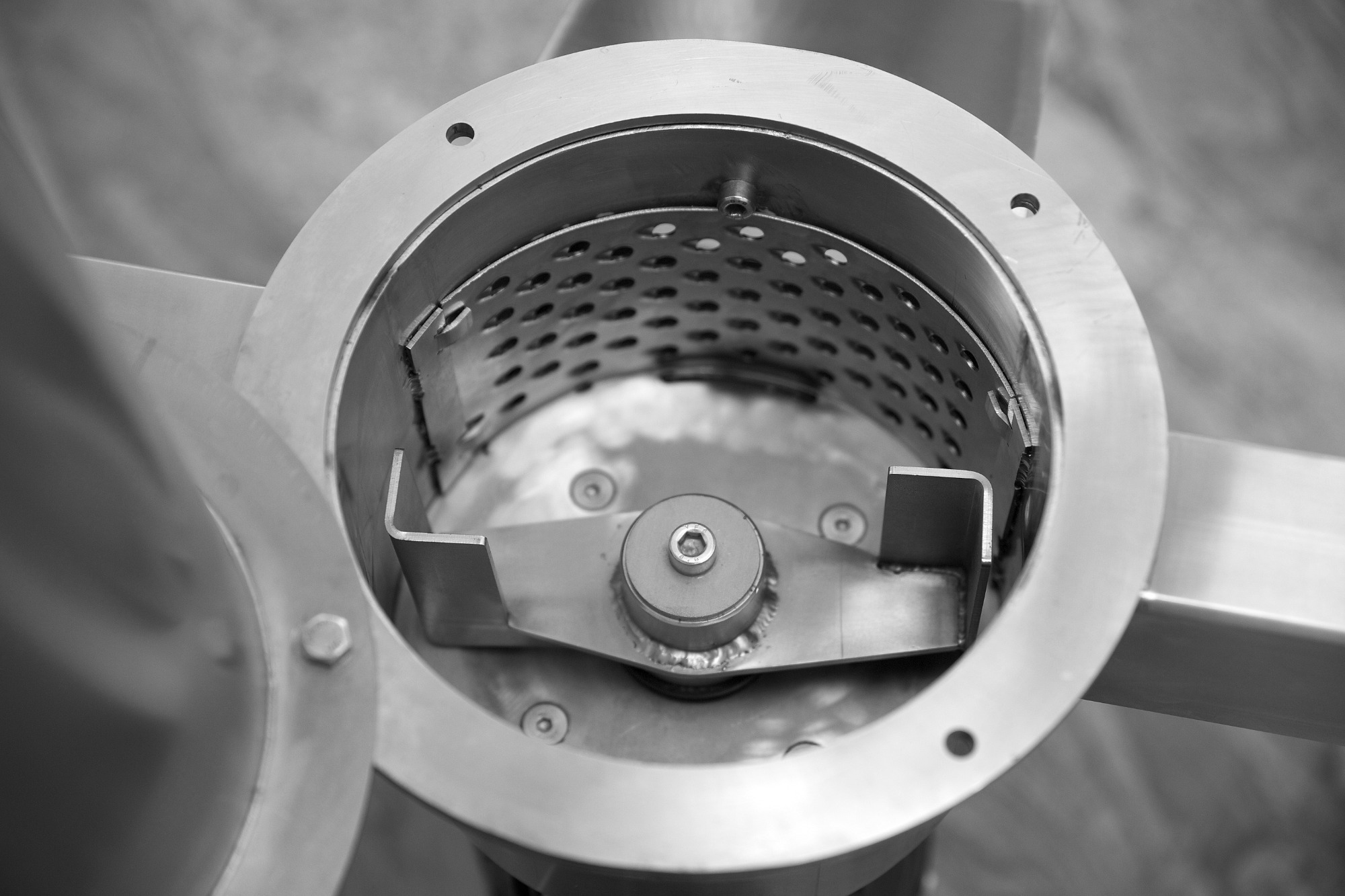

Electric apple crusher with knives and a grater/sieve

Through the funnel, the apples enter the grinding chamber, where they are crushed into a fine fraction with the help of knives and a section with a grater (or sieve) and exit through the installed sieve.

The sieves are interchangeable, allowing for the necessary fraction of crushed apples to be achieved.

Figure 9. Electric crusher MULIPLUS (Manufacturer: ZAMBELLI Enotech s.r.l.)

Electric apple crusher with a pusher and grater/sieve

Through the funnel, the apples enter the grinding chamber, where they are crushed into a fine fraction with the help of a pusher and a section with a grater (or sieve) and exit through the installed sieve. The sieves are interchangeable, allowing for the necessary fraction of crushed apples to be achieved.

Figure 10. Electric crusher MMS (Manufacturer: Zottel d.o.o.)

Electric apple crusher with a large diameter crushing cylinder and pusher

The crusher has a large crushing cylinder made of stainless steel installed in its body. Apples are poured into the hopper and fall between the crushing cylinder and the pusher. With the help of reciprocating movements of the pusher, the apples are pressed against the cylinder, and the crushing of the apples occurs. By the way, the old models of VORAN crushers used this very design of the crusher with an automatic pusher mechanism.

Figure 11. Electric apple crusher RINK (Manufacturer: Helmut Rink GmbH)

Figure 12. Apple crusher with an automatic pusher mechanism (Manufacturer: voran Maschinen GmbH)

Figure 13. Apple crusher with an automatic pusher mechanism (Manufacturer: voran Maschinen GmbH)

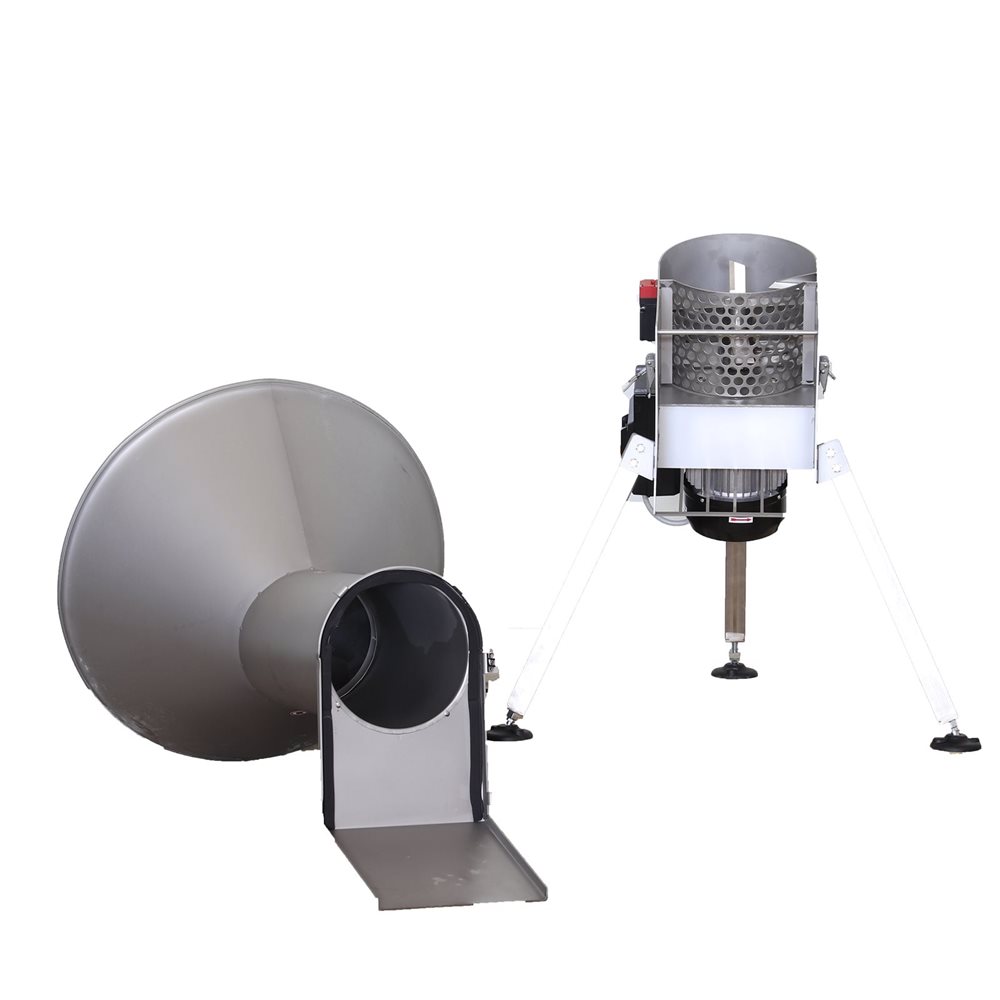

Electric apple crusher with a toothed disc

A stainless steel disc with several rows of teeth is mounted on the motor shaft, which works as a crusher rather than a grater. By changing the position of the outlet flap, the degree of crushing of the fruits can be adjusted.

Figure 14. Electric apple crusher Apster 2500 (Manufacturer: Masito OU)

Alternative methods

For crushing apples, a powerful juicer with a large grater or a food processor can be used. A feed grinder or grain grinder with a disc for crushing root vegetables, for example, a household feed grinder IK-1 (Manufacturer: OAO "Mogilevliftmash"), is also suitable for crushing.

Figure 15. Household feed grinder IK-1 (Manufacturer: OAO "Mogilevliftmash")

Choosing an apple crusher

Material of manufacture

Any part of the crusher that comes into contact with apple juice should be made of natural wood, stainless steel, plastic, or painted metal.

It is best to choose a crusher made entirely of food-grade stainless steel grades 08X18N10 (AISI304) or 10X17N13M2T (AISI 316).

Some parts of the crusher may be made of oak or beech. These types of wood are characterized by high strength and do not release any harmful substances into the juice.

Resulting fraction

The optimal size of apple pieces when crushing is about 6-8 mm (just like you would grate carrots on a large grater). This size is optimal for pressing. Too fine a fraction will clog the filter bag. Too large pieces of apples will not press well. It is worth noting that when crushing apples, the seeds should remain intact, which helps avoid undesirable bitterness in the juice.

Figure 16. Resulting fraction using the electric apple crusher ESE-055 (Manufacturer: APPLE PRESS LTD.)

Quality of manufacturing

If you are buying a stainless steel crusher, pay attention to the welds. Signs of overheating (burning) of the metal are unacceptable. All seams should be treated after welding, and the protective oxide layer that enhances its corrosion resistance should be restored. This process is called passivation.

Figure 17. Treated seam after welding

Also, pay attention to the quality of the root of the seam. To obtain a proper, quality seam during welding, backing gas (supply of protective gas to the reverse side of the seam) is necessary. Otherwise, the reverse side of the seam oxidizes, pores and inclusions occur in the root of the seam, and corrosion resistance is lost (even after subsequent passivation).

Figure 18. Root of the seam (1 - welding without backing gas, 2 - signs of overheating after welding with backing gas, 3 - passivated root of the seam)

Processed parts of the crusher should not have deep scratches from grinding and scratches. All of this can become a source of corrosion and bacterial growth in the future.

When in contact with acidic juice, rust can form in such places, and the final product may acquire a metallic taste.

In the food and pharmaceutical industries, such seams are considered unhygienic. Microorganisms can accumulate in porous, oxidized areas, which is dangerous. Therefore, stainless steel containers usually have a mirror-like inner surface and do not have corners so that they can be easily cleaned.

Metal parts should not have sharp edges, signs of rust, and deep scratches should be removed,