Pastorizzatore elettrico per succo PA180E

Express Post - Consegna a Latvia (1 giorni lavorativi) - 61.09€

UPS Standard - Consegna a Latvia (2 giorni lavorativi) - 73.31€

Itella Smartpost - Consegna a Latvia (2 giorni lavorativi) - 87.97€

Itella Smartpost Parcel Locker - Consegna a Latvia (2 giorni lavorativi) - 87.97€

Latvian Post - Consegna a Latvia Prioritario (1–2 settimane) - 87.97€

UPS Express - Consegna a Latvia (1 giorni lavorativi) - 87.97€

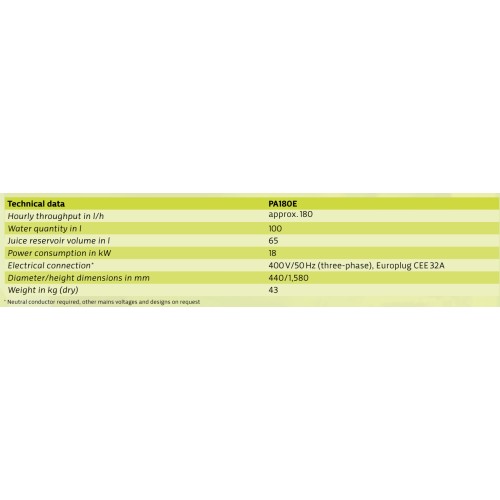

- Portata oraria: ca. 180 l/h

- Serbatoio succo: 65 l

- Contenuto d'acqua: 100 l

- Materiale: 1.4301 / AISI 304

- Consumo di energia: 18 kW

- Connessione elettrica: 400V/50Hz (trifase), Europlug CEE32A (Conduttore neutro richiesto, altre tensioni di rete e design su richiesta)

- Dimensioni diametro/altezza in mm: 440/1.580 mm

- Peso: (senza dispositivo di riempimento) 49 kg

- Altezza: (senza dispositivo di riempimento) 1 650 mm

- Larghezza: (senza dispositivo di riempimento) 600 mm

- Fornitura: incl. 2 valvole di riempimento bottiglie o sistema di riempimento per Bag in Box

- Prodotto in Austria

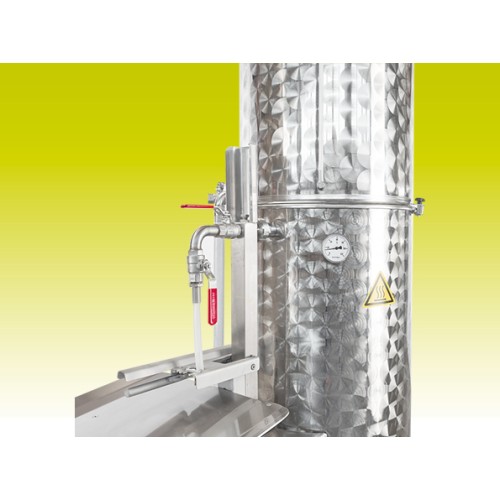

Elettropastorizzatore con serpentina di riscaldamento e scambiatore di calore a tubo. Funzionamento semplice grazie al controllo manuale del flusso e al display digitale per supervisionare la temperatura. L'uso del sistema di riempimento a 2 bottiglie consente di riempire diverse dimensioni di bottiglie allo stesso tempo. Questo pastorizzatore è disponibile anche con un sistema di riempimento per Bag in Box.

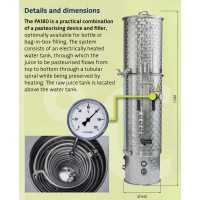

Il PA180 è una combinazione pratica di un dispositivo di pastorizzazione e riempitrice, disponibile opzionalmente per riempimento bottiglie o bag-in-box. Il sistema è costituito da un serbatoio d'acqua riscaldato elettricamente, attraverso il quale il succo da pastorizzare scorre dall'alto verso il basso mediante una spirale tubolare mentre viene conservato dal riscaldamento. Il serbatoio del succo crudo si trova sopra il serbatoio d'acqua.

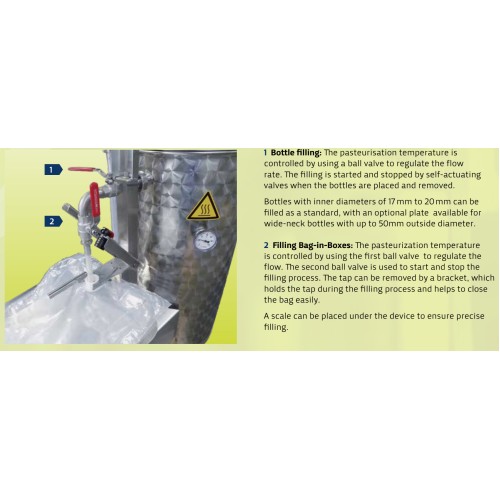

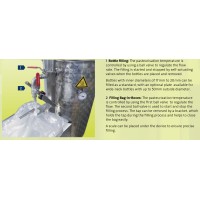

Riempimento bottiglie: La temperatura di pastorizzazione è controllata usando una valvola a sfera per regolare la portata. Il riempimento viene iniziato e arrestato da valvole auto-attuanti quando le bottiglie vengono collocate e rimosse. Bottiglie con diametri interni da 17 mm a 20 mm possono essere riempite come standard, con una piastra opzionale disponibile per bottiglie a bocca larga con diametro esterno fino a 50 mm.

Riempimento Bag-in-Boxes: La temperatura di pastorizzazione è controllata usando la prima valvola a sfera per regolare il flusso. La seconda valvola a sfera viene utilizzata per avviare e arrestare il processo di riempimento. Il tappo può essere rimosso mediante un supporto, che tiene il tappo durante il processo di riempimento e aiuta a chiudere facilmente il sacchetto. Una bilancia può essere posizionata sotto il dispositivo per garantire un riempimento preciso.

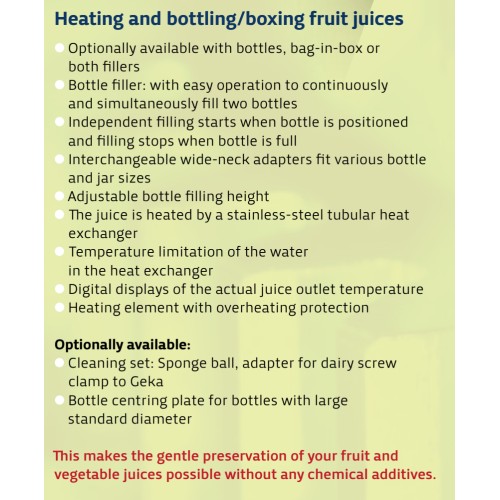

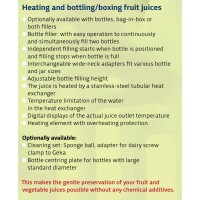

Riscaldamento e imbottigliamento/confezionamento di succhi di frutta

- Disponibile opzionalmente con riempitori per bottiglie, bag-in-box o entrambi

- Riempitore di bottiglie: con facile operazione per riempire due bottiglie in modo continuo e simultaneo

- L'avvio del riempimento avviene in modo indipendente quando la bottiglia è posizionata e il riempimento si ferma quando la bottiglia è piena

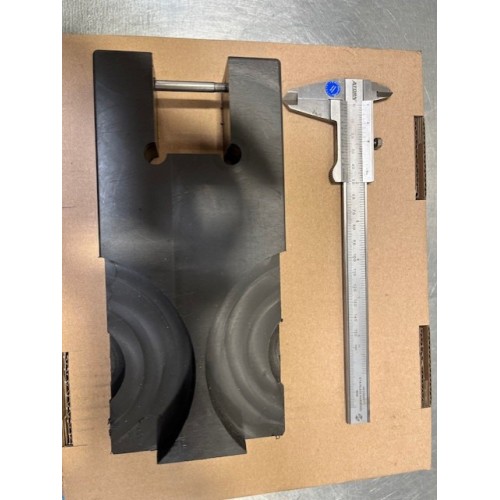

- Adattatori intercambiabili a bocca larga si adattano a varie dimensioni di bottiglia e barattolo

- Altezza di riempimento bottiglie regolabile

- Il succo viene riscaldato da uno scambiatore di calore tubolare in acciaio inossidabile

- Limitazione della temperatura dell'acqua nello scambiatore di calore

- Display digitali della temperatura effettiva all'uscita del succo

- Elemento riscaldante con protezione contro il surriscaldamento

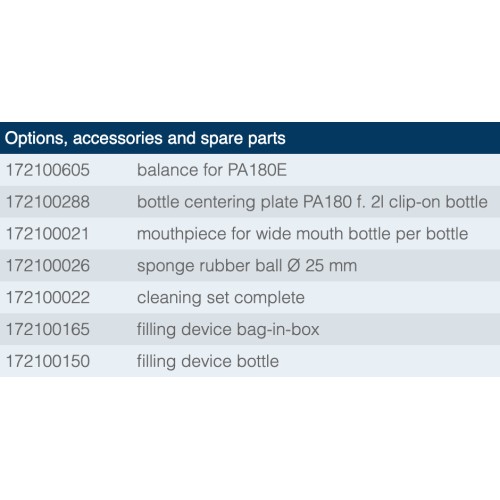

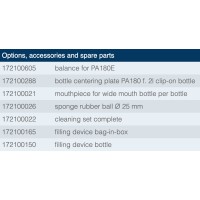

Disponibile su richiesta:

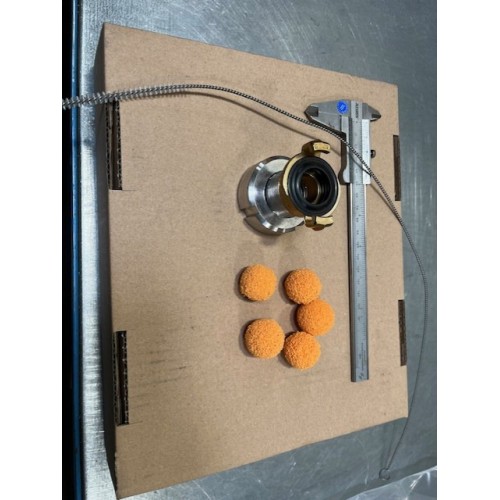

- Set di pulizia: Palla in spugna, adattatore per morsetto a vite da latticini a Geka

- Piastra di centraggio per bottiglie con diametro grande standard