Bag-in-Box® un “Stand up Pouch” pusautomātiska pildīšanas iekārta SEMIFLOW

Express Post - Delivery to Latvia (1 business days) - 61,09€

UPS Standard - Delivery to Latvia (2 business days) - 73,31€

Itella Smartpost - Delivery to Latvia (2 business days) - 87,97€

Itella Smartpost Parcel Locker - Delivery to Latvia (2 business days) - 87,97€

Latvijas Pasta - Delivery to Latvia Priority (1-2 weeks) - 87,97€

UPS Express - Delivery to Latvia (1 business days) - 87,97€

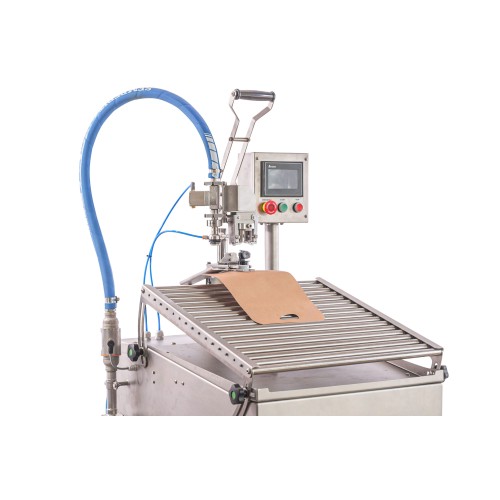

Bag in Box pildīšanas mašīna SEMIFLOW ir paredzēta karstu un aukstu šķidrumu pildīšanai Bag in Box un Stand up Pouch iepakojumos.

Mašīna piepilda iepakojumus automātiski. Vienkārši ievietojiet maisu vai paciņu Bag in Box pildītājā un pavelciet rokturi. Pēc tam, kad iepakojums ir piepildīts, atgrieziet pildīšanas rokturi sākuma pozīcijā un aizkorķējiet maisu.

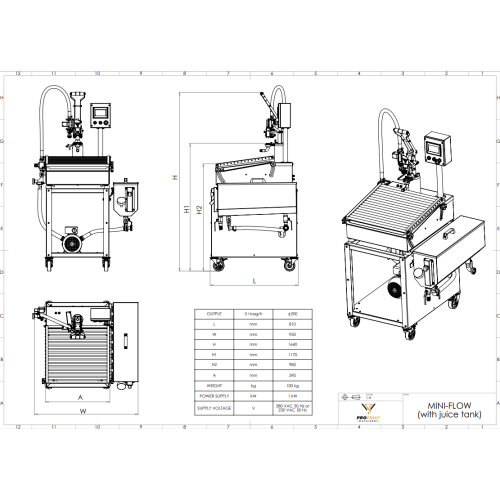

Kapacitāte – 250 gab. 3 L maisi stundā

- Lieliski piemērota dažādu šķidrumu pildīšanai: no sulas, vīna, piena līdz buljonam, eļļai, ziepēm u.c.

- Pilda Bag in Box maisus izmēros no 1–30 L, Stand up Pouch pakas izmēros no 0,75–5 L.

- Piemērota gan karstai, gan aukstai pildīšanai.

- Mašīna pilda gan Bag in Box, gan Stand up Pouch pakas ar krānu.

- Pildītājam var būt papildu noņemams rezervuārs karstai pildīšanai. Tas ir ērti uzmontēts uz mašīnas sāniem labākai pārbaudei un vieglākai mazgāšanai. Rezervuārs arī samazina šķidruma putošanos karstās pildīšanas procesā.

- Rezervuāram ir integrēta šķidruma līmeņa kontrole, lai regulētu pārmērību un līmeni rezervuārā. Rezervuārs arī savienojas ar mūsu pasterizētāju.

- Tilpuma atkārtojamības kļūda ir tikai ± 0,5 %.

- Pildītājs pirms pildīšanas evakuē maisus un paciņas.

- Nāk ar skārienjutīgu paneli un daudzvalodu izvēlni.

- Viegli pielāgojams pildīšanas galds ļauj viegli piepildīt dažādus Bag in Box un Stand up Pouch iepakojumus.

- Galda darba virsma sastāv no konveijera rullīšiem, kurus ir viegli tīrīt un kas palīdz maisu un paciņu gludai slīdēšanai.

- Pēc darba pildītāju ir viegli notīrīt ar ārējo un CIP tīrīšanu.