Villimisseade pudelite L-INOX

Express Post - Kohaletoimetamine: Latvia (1 tööpäeva) - 61.09€

UPS Standard - Kohaletoimetamine: Latvia (2 tööpäeva) - 73.31€

Itella Smartpost - Kohaletoimetamine: Latvia (2 tööpäeva) - 87.97€

Itella Smartpost Parcel Locker - Kohaletoimetamine: Latvia (2 tööpäeva) - 87.97€

Latvian Post - Kohaletoimetamine: Latvia Prioriteetne (1–2 nädalat) - 87.97€

UPS Express - Kohaletoimetamine: Latvia (1 tööpäeva) - 87.97€

Filler bottling machines are designed to transfer wine, vinegard, brandy,syrup, juice etc... from storage tanks or barrels into bottles in a controlled, hygienic, and precise manner. It plays a crucial role in the bottling process, ensuring that the wine maintains its quality, aroma, and consistency from production to final packaging.

The primary function of a filler machine is to fill each bottle with an exact and uniform amount of wine while minimizing exposure to oxygen. Reducing oxygen contact is essential to prevent oxidation, which can negatively affect the taste, aroma, and overall stability of the wine. Modern wine fillers are designed to operate smoothly, preventing foaming and product loss during the filling process.

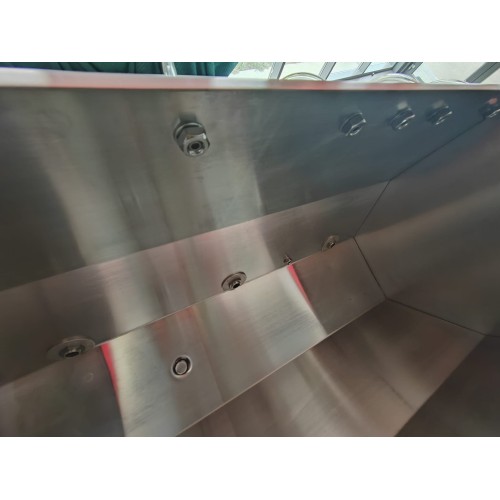

Wine fillers also improve hygiene and safety standards. They are typically made from stainless steel and other food-grade materials, allowing for easy cleaning and sanitization. This helps prevent contamination and ensures compliance with food production regulations.

Manual gravity wine filler

- Suitable for home winemakers

- Affordable

- Slower but simple to use

A gravity wine filler made of stainless steel (inox) is designed for simple, hygienic, and accurate bottle filling using gravity (no pump required).

Below are the main components of such a system:

1. Tank / Supply Reservoir

Holds the wine before filling. Made of stainless steel (open or closed type). Ensures consistent liquid supply to the filling valves.

2. Connection Pipes and Valves

Connect the tank to the filling nozzles. Equipped with manual or automatic shut-off valves. Allows controlled product flow.

3. Filling Nozzles (Gravity Valves)

4 or 6 nozzles for simultaneous filling. Designed to reduce foaming and overflow.

4. Frame / Supporting Structure

Wheeled stainless steel construction supporting tank and nozzles.