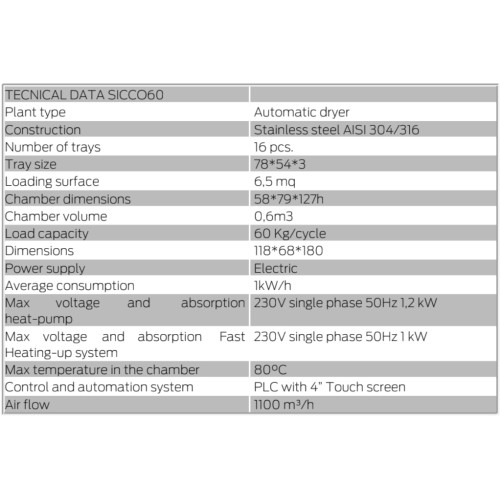

Dörrautomat SICCO60 - Trocknen von beispielsweise Pilzen, Obst, Gemüse oder Kräutern geeignet

Express Post - Lieferung nach Latvia (1 Werktage) - 61.09€

UPS Standard - Lieferung nach Latvia (2 Werktage) - 73.31€

Itella Smartpost - Lieferung nach Latvia (2 Werktage) - 87.97€

Itella Smartpost Parcel Locker - Lieferung nach Latvia (2 Werktage) - 87.97€

Latvian Post - Lieferung nach Latvia Priorität (1–2 Wochen) - 87.97€

UPS Express - Lieferung nach Latvia (1 Werktage) - 87.97€

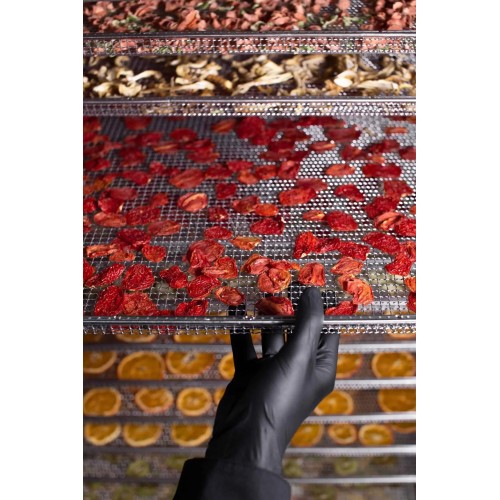

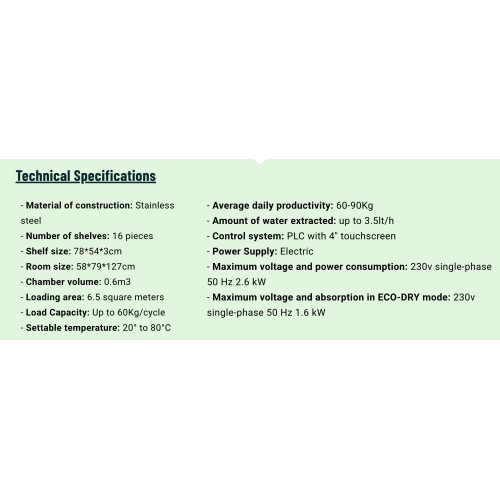

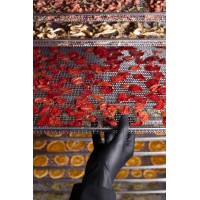

SICCO60 PROFESSIONELLER TROCKNER/DEHYDRIERGERÄT ist das ideale System für alle, die nach einem professionellen System zum Trocknen von Lebensmitteln suchen. Vollständig aus Edelstahl gebaut, ist es funktional und intuitiv. Es ermöglicht Ihnen, einfache, sichere, präzise und effiziente Trocknungsprozesse durchzuführen. Der SICCO60 arbeitet vollautomatisch. Er nutzt die Technologie der Trocknung im geschlossenen Kreislauf, die erhebliche Energieeinsparungen garantiert, indem sie eine perfekte Standardisierung des Prozesses gewährleistet, egal wo der Trockner positioniert ist. Er ermöglicht es, bei niedriger Temperatur auf "schonende" Weise zu trocknen, um eine hervorragende Rehydratation und den Erhalt der meisten organoleptischen Eigenschaften sicherzustellen. Ideal zum Trocknen von: Obst, Gemüse, Blumen, Kräutern, Blättern, Pilzen, Trüffeln, Beeren, Nudeln, Fleisch, Fisch, etc.

Systeme:

> Automatisches-dynamisches Trocknungssystem mit der Möglichkeit, bis zu 24 Phasen während des Zyklus einzustellen. Für jede Phase können Temperatur (von 20°C bis 80°C), relative Luftfeuchtigkeit (RF%) und Prozesszeit festgelegt werden. Das System ermöglicht es, bis zu 3 Rezepte zu speichern.

> Automatisches-statisches Trocknungssystem mit der Möglichkeit, Temperatur (von 20°C bis 80°C) und relative Luftfeuchtigkeit (RF%) einzustellen.

> ECO-DRY Energiesparsystem zur Reduzierung des Verbrauchs in der Heizphase auf nur 1,2kW.

> Schnellheizungssystem zur automatischen Erhöhung der Leistung in den Heizphasen und Reduzierung der Trocknungszeiten.

> Prozesssystem im geschlossenen Kreislauf, ausgelegt zur Optimierung des Verbrauchs und der Verarbeitungszeiten, Erhaltung der Effizienz an jedem Ort und das ganze Jahr, Vermeidung des Eindringens von Schadstoffen in den Raum, Vermeidung von Energieverlusten und der Entstehung von Totzonen im Inneren der Kammer.

AUTOMATISCHE SYSTEMSTEUERUNG ausgestattet mit:

- Bedieneroberfläche mit 4,3" resistivem Farb-Touchscreen-Grafikdisplay für einfache und intuitive Steuerung.

- Automatisierung durch SPS und Verwaltungssoftware für die vollständige Kontrolle aller Prozesse, die es dem Kunden ermöglicht, alle oben aufgeführten automatischen Systeme zu starten, aber auch die spezifischen Parameter jedes Prozesses zu ändern.

- Einstellung, Speicherung und Echtzeitanzeige aller Parameter, die sich auf die Prozesse beziehen (Temperatur, relative Luftfeuchtigkeit und Zeit).

- Speicherung von n. 3 vollständig anpassbaren Trockenprogrammen mit n. 24 einstellbaren Phasen.

- Echtzeitanzeige eines Zeit-/Temperatur-Feuchtigkeitsdiagramms in Bezug auf die letzten 120 Minuten des Prozesses.

- Echtzeitanzeige der in Betrieb befindlichen Anlagenteile.

- System für Diagnosen und Erkennung von Fehlfunktionen.

- Zugriff auf die Einstellung der Prozesse unter einem Sicherheitskennwort.

- Menüs, die sich den spezifischen Funktionen der Schnellaufheizung und Luftabfuhr während des Prozesses widmen.

Allgemeine Konstruktionsmerkmale des SICCO60:

- - Edelstahlstruktur

- - Trocknungskammer aus isoliertem Edelstahl

- - hermetische Tür aus Edelstahl mit Glaspförtchen zur Betrachtung des Produkts während des Trocknens.

- - n.4 Räder zur Erleichterung der Positionierung und Reinigungsarbeiten

- - Wärmedämmung mit ungiftigem Material

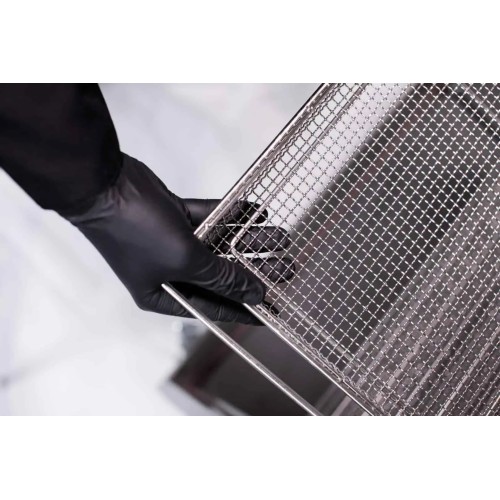

- - 16 Tabletts mit Edelstahlgittern zur Platzierung des zu trocknenden Produkts. Leicht, widerstandsfähig und einfach zu reinigen.

- -Elektrisches und Managementsystem gemäß den CE-Normen