Полуавтоматическая установка для розлива сока в пакеты Bag-in-Box® и “Stand up Pouch” SEMIFLOW

Express Post - Доставка в Latvia (1 рабочих дней) - 61.09€

UPS Standard - Доставка в Latvia (2 рабочих дней) - 73.31€

Itella Smartpost - Доставка в Latvia (2 рабочих дней) - 87.97€

Itella Smartpost Parcel Locker - Доставка в Latvia (2 рабочих дней) - 87.97€

Latvian Post - Доставка в Latvia Приоритет (1-2 недели) - 87.97€

UPS Express - Доставка в Latvia (1 рабочих дней) - 87.97€

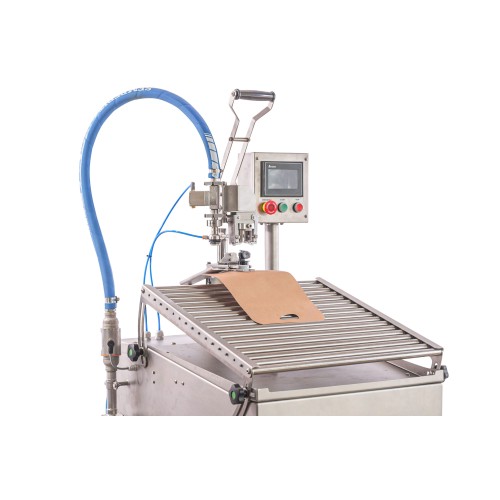

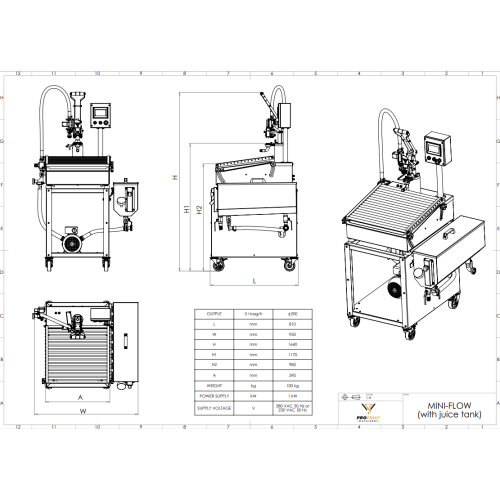

Машина для наполнения Bag in Box SEMIFLOW предназначена для розлива горячих и холодных жидкостей в упаковки Bag in Box и Stand up Pouch.

Машина автоматически наполняет упаковки. Просто вставьте пакет или упаковку в наполнитель Bag in Box и потяните за ручку. После наполнения упаковки верните ручку наполнения в начальное положение и закройте пакет крышкой.

Производительность – 250 шт. пакетов по 3 л/ч

- Идеально подходит для наполнения различных жидкостей: от сока, вина, молока до бульона, масла, мыла и т. д.

- Наполняет пакеты Bag in Box объемом 1–30 л, упаковки Stand up Pouch объемом 0,75–5 л.

- Подходит для как горячего, так и холодного наполнения.

- Машина наполняет как упаковки Bag in Box, так и Stand up Pouch с краником.

- Наполнитель может иметь дополнительный съемный буферный бак для горячего наполнения. Он удобно монтируется на боковой стороне машины для лучшего осмотра и более легкого процесса мойки. Буферный бак также снижает пенообразование жидкости во время процесса горячего наполнения.

- В буферном баке есть встроенное управление уровнем жидкости для регулирования перелива и уровня в баке. Буферный бак также подключается к нашему пастеризатору.

- Ошибка повторяемости объема составляет всего ± 0,5 %.

- Наполнитель предварительно вакуумирует пакеты и упаковки перед наполнением.

- Оснащен сенсорной панелью и многоязычным меню.

- Легко регулируемая столешница позволяет легко наполнять пакеты Bag in Box и Stand up Pouch различного объема.

- Рабочая поверхность стола состоит из конвейерных роликов, которые легко чистятся и способствуют плавному скольжению пакетов и упаковок.

- Наполнитель легко чистить после работы с помощью внешней и CIP очистки.