Перистальтический насос ZETA-PE – для измельченной фруктовой / виноградной массы

Express Post - Доставка в Latvia (1 рабочих дней) - 30.55€

UPS Standard - Доставка в Latvia (2 рабочих дней) - 36.65€

Itella Smartpost - Доставка в Latvia (2 рабочих дней) - 43.99€

Itella Smartpost Parcel Locker - Доставка в Latvia (2 рабочих дней) - 43.99€

Latvian Post - Доставка в Latvia Приоритет (1-2 недели) - 43.99€

UPS Express - Доставка в Latvia (1 рабочих дней) - 43.99€

- СДЕЛАНО ИЗ НЕРЖАВЕЮЩЕЙ СТАЛИ AISI 304

- ДВУСТОРОННЯЯ СИСТЕМА ВАКУУМА (Л-П)

- БЕЗ ВОДЫ

- ГЛУБОКАЯ САМОВСАСЫВАЮЩАЯ СПОСОБНОСТЬ

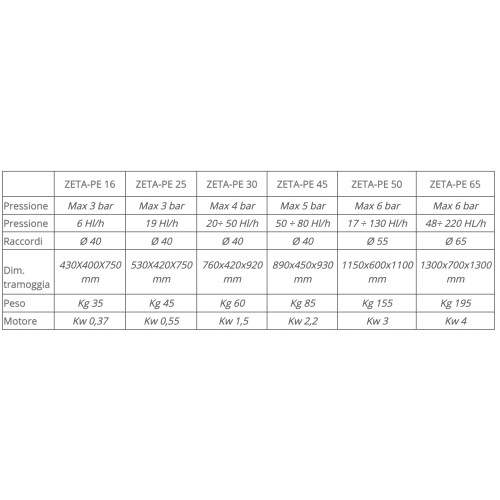

- 1 СКОРОСТЬ ДЛЯ Z-PE 16

- ЧАСТОТНЫЙ РЕГУЛЯТОР ДЛЯ Z-PE 30/45/50/65

- СДЕЛАНО В ИТАЛИИ

Перистальтические насосы имеют наиболее мягкое движение среди насосов для вина/сусла. Благодаря соединению с бункером (опционально) можно переносить жидкости с кашеобразной консистенцией, осадок, отделенные винограды и другие пищевые продукты. Тип работы обеспечивает равномерную подачу, ограниченное раздавливание и полное отсутствие нагрева продукта. Резиновый шланг сжимается вращающимися алюминиевыми роликами, установленными на подшипниках для минимального трения. Резиновый шланг смазывается на заводе пищевой смазкой и не требует периодического смазывания. Машина полностью изготовлена из нержавеющей стали, включая компоненты, не находящиеся в прямом контакте с перекачиваемой жидкостью.

Преимущества и характеристики:

- Частотное регулирование скорости на всех блоках.

- Скорость регулируется с панели управления (стандарт)

- Долговременный дистанционный пульт [вперед/назад, стоп/старт и скорость] (опция)

- Самовсасывание на глубину до 7 м.

- Максимальное рабочее давление 6 бар (по запросу до 15 бар с вакуумной системой)

- Реверсивный поток

- Шланг не требует смазки. Пищевая шланг смазывается на производстве и не требует периодического смазывания

- Вращающиеся алюминиевые ролики уменьшают трение и продлевают срок службы шланга

- Компенсаторы давления на входе и выходе устраняют 'стук'

- Опциональный выключатель давления

- Опциональные бункеры для сусла/выжимок. Выбор между интегрированными и свободно стоящими; интегрированные бункеры соединяются с насосами — входной фланец насоса прикрепляется к выходному фланцу бункера. Нержавеющий бункер и шнек. Двигатель с редуктором. Занимает ~15 минут для прикрепления/удаления бункера

- Опциональный вакуум для большего потока; особенно полезен для сусла

- Опциональный двойной уровень поплавкового контроля для бункера

- Автоматическое отключение при повреждении/разрыве резиновой трубки

- Легкая очистка с использованием циклов "C.I.P." (очистка на месте)

СИСТЕМА НЕПРЕРЫВНОГО ВАКУУМА:

Вакуумная система увеличивает скорость потока. Она особенно полезна при перекачке сусла или выжимок. Скорость перекачки сусла и выжимок может быть увеличена до 40% с этой опцией. Вакуум также увеличивает глубину всасывания до 8 метров.