Гидравлический пресс для сока + Измельчитель KOMBI-30

Itella Smartpost Parcel Locker - Доставка в Latvia (2 рабочих дней) - 15.00€

Itella Smartpost - Доставка в Latvia (2 рабочих дней) - 46.63€

Express Post - Доставка в Latvia (1 рабочих дней) - 61.09€

UPS Standard - Доставка в Latvia (2 рабочих дней) - 66.09€

Latvian Post - Доставка в Latvia Приоритет (1-2 недели) - 234.30€

UPS Express - Доставка в Latvia (1 рабочих дней) - 515.29€

- Емкость корзины: 30 литров

- Мощность двигателя: 1,5 кВт

- Скорость вращения двигателя: 1500 об/мин

- Напряжение сети: 230В, 50 Гц / 400В, 50 Гц

- Габариты и вес пресса: 900 x 650 x h1400, 140 кг

- Габариты и вес упаковки: 80x60x150см, 150кг

- Сделано в Чешской Республике

Эта машина сочетает в себе измельчитель и пресс для фруктов. Конструктивно это устройство решено как единая машина. Обслуживание не требует больших усилий и может выполняться одним человеком.

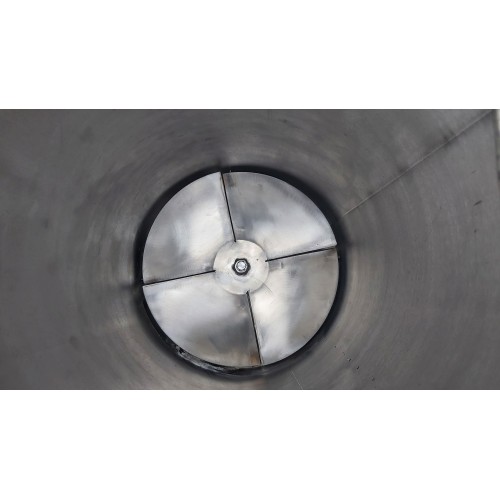

Измельчитель и пресс оборудованы колесами и ручкой для ручного перемещения по тротуару или в саду. Бункер для дробления, куда засыпают фрукты, окрашен пищевой краской. Фрукты измельчаются на колесе из нержавеющей стали со скоростью 1500 об/мин. Высокие обороты обеспечивают отсутствие грубых кусочков в результате, что дает нам пюре, подходящее для последующего прессования. Корзина для прессования с тряпкой, в которую падают измельченные фрукты, изготовлена из нержавеющей стали и имеет объем 30 литров. Фрукты прессуются гидравлическим поршнем под давлением до 3 тонн. Все устройство питается от одного электродвигателя мощностью 1,5 кВт / 230 В.

Почти все фрукты и овощи подходят для измельчения. Например: яблоки, груши, бананы, нектарины, персики, апельсины, свекла, морковь и т.д. Для прессования в основном подходят яблоки, груши, нектарины, апельсины. Всегда на ваше усмотрение.

НОВОЕ: мы недавно начали производить расширенный бункер из нержавеющей стали. Бункер был расширен в квадратную форму. Фрукты можно загружать в машину прямо из ведра, не падая на землю. Мы также улучшили вывод из дробилки. Теперь измельченный материал намного лучше выбрасывается в корзину пресса.