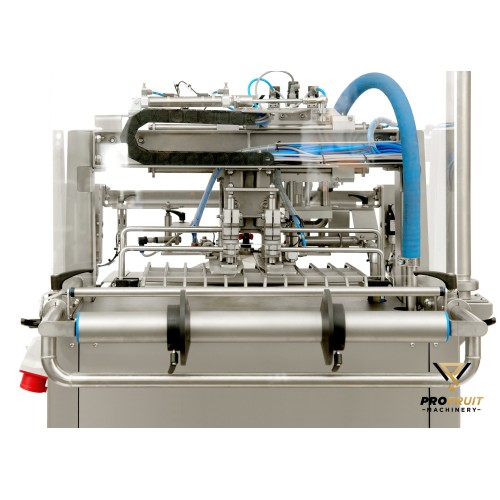

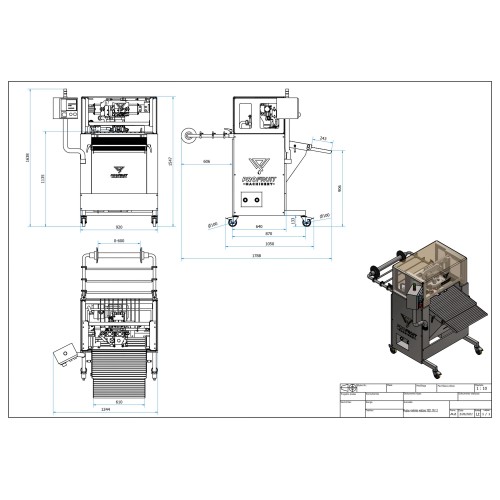

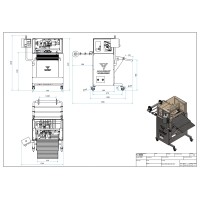

Автоматическая установка для розлива сока в пакеты Bag-in-Box® MAXIFLOW

Express Post - Доставка в Latvia (1 рабочих дней) - 61.09€

UPS Standard - Доставка в Latvia (2 рабочих дней) - 73.31€

Itella Smartpost - Доставка в Latvia (2 рабочих дней) - 87.97€

Itella Smartpost Parcel Locker - Доставка в Latvia (2 рабочих дней) - 87.97€

Latvian Post - Доставка в Latvia Приоритет (1-2 недели) - 87.97€

UPS Express - Доставка в Latvia (1 рабочих дней) - 87.97€

Автоматический наполнитель пакетов Bag in Box MAXIFLOW полностью автоматически наполняет жидкости в соединенные и отдельные пакеты Bag in Box. Наполнитель также может использоваться для заполнения пакетов Pouch.

Машина обеспечивает полностью автоматический процесс наполнения для соединенных пакетов Bag in Box. После вставки первого пакета, машина снимает крышку, наполняет жидкость и закрывает пакет. Затем она выпускает заполненный пакет и берет следующий для наполнения. Таким образом, процесс наполнения является непрерывным, и оператору необходимо только вынуть заполненный пакет из машины.

Для заполнения отдельных пакетов Bag in Box или Pouch вставьте упаковку в наполнитель и нажмите кнопку START — машина автоматически снимает кран, вакуумирует пакет, наполняет его жидкостью и закрывает пакет.

Производительность: ~2000 л/ч.

- Идеально для наполнения различных жидкостей: от сока, вина, молока до бульона, масла, мыла и т. д.

- Простой в использовании механизм выполняет всю работу автоматически. Кроме того, пакеты могут подаваться в машину вручную (отдельные пакеты или поучи) или автоматически (пакеты в ленте).

- Подходит как для горячего, так и для холодного наполнения.

- Машина наполняет пакеты Bag in Box объемом 1–30 л, а также пакеты Stand up Pouch объемом 0,75–5 л.

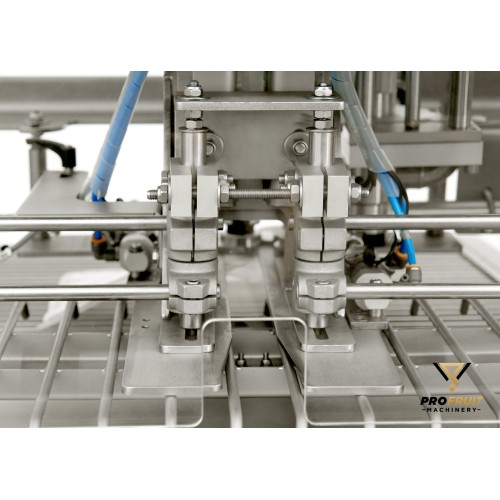

- Машина наполняет упаковки с закрытием крана. Также возможно заполнение упаковок с различными закрытиями по запросу.

- Лазерный защитный механизм защищает конечности, автоматически останавливая и отменяя процесс наполнения в случае аварии.

- Машина изготовлена из материалов из нержавеющей стали (AISI 304).

- Сенсорная панель управления и многоязычное меню облегчают работу.

- Ошибка повторяемости объемов составляет всего ± 0,3 %.

- Возможен дополнительный стол для наполнения, который скользит под основным столом для наполнения пакетов большего объема (от 20 до 30 л).

- Наполнитель легко чистить после работы с помощью внешней и CIP очистки.

- Рабочая поверхность стола состоит из конвейерных роликов, которые исключительно легки в чистке.

- Все части имеют защиту от воды IP 65.